Kaplan Hydro Turbine(axial-flow turbine) for low water head from 3m to 30m.

Kaplan Hydro turbine is mostly suitable for hydropower stations with low water head and high flow rates, are mostly used in run-of-river power stations.

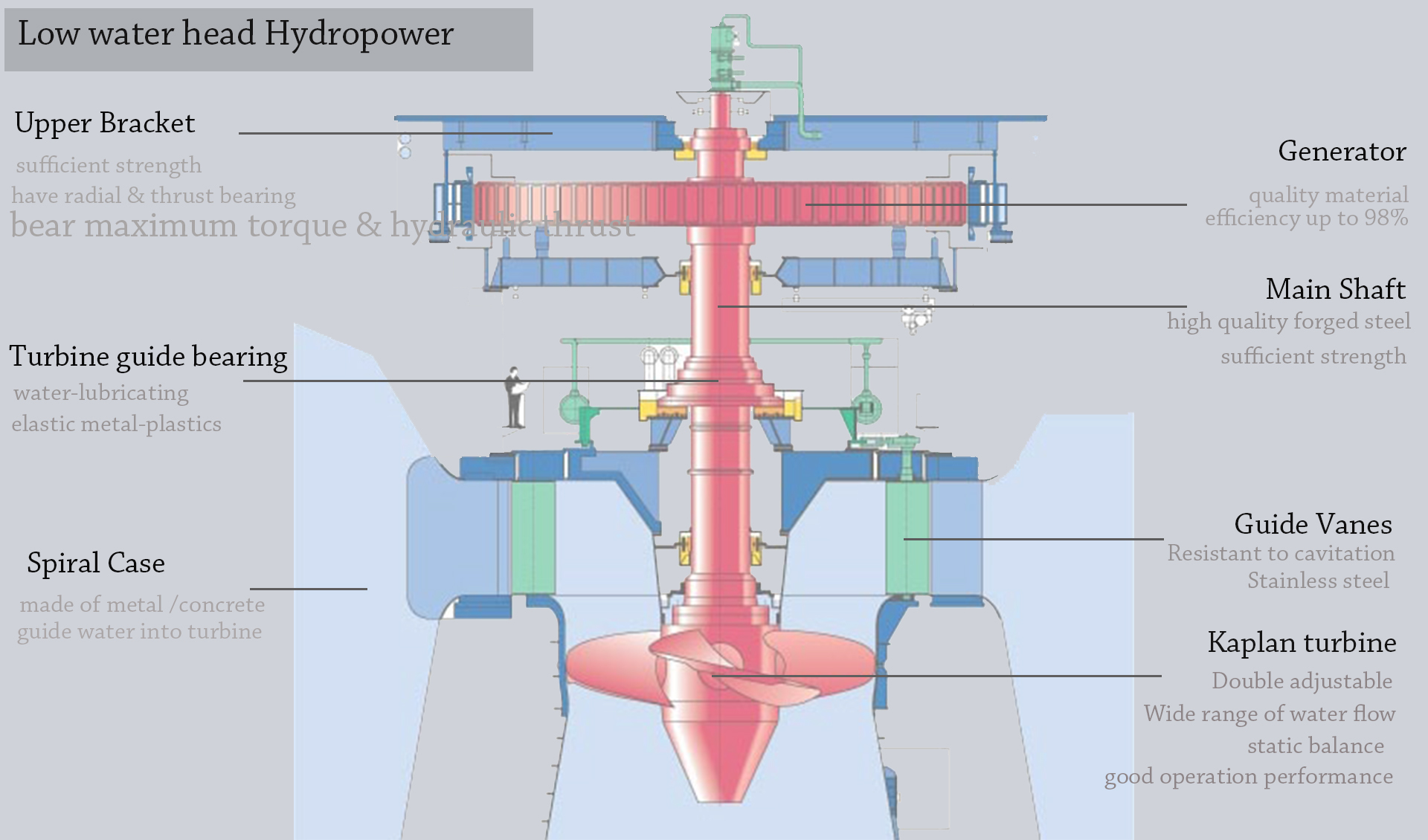

Kaplan turbine belonging reaction turbine, which is mainly composed of turbine runner, the runner chamber, water guide distribution, spiral case etc.

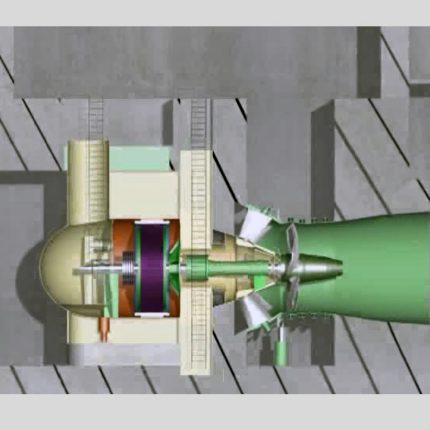

The Kaplan hydro turbine with vertical shaft arrangement, with three types as open flume, pressure flume, and seal off (concrete/metal spiral case).

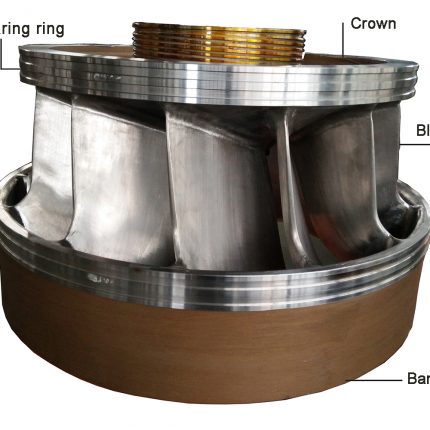

Kaplan runner blade structure have two types: fixed propeller and adjustable propeller.

The fixed-propeller Kaplan turbine, blades are fixed on the runner body, and the blade installation angle cannot be changed during operation. The efficiency curve is steep. It is suitable for power stations where load changes are small or the number of units can be adjusted to adapt to load changes. Advantages: simple structure and low cost. Disadvantages: efficiency will drop sharply when deviating from the design conditions. According to its characteristics, it is generally used for hydropower stations with small output, low water head and small water head changes.

The adjust-propeller type is equipped with a set of operation and transmission mechanism to make the blades rotate in the runner hub. The number of runner blades is generally 4~6. It has double adjustment performance, that is, the water guide vanes and the runner blades can be adjusted. Therefore, the Kaplan turbine can maintain the stability and high efficiency of the turbine within a large range of water head and load changes, so it is more widely used than the fixed-propeller turbine.

Runner blades made of stainless steel, and CNC machined, have good performance.

How the Kaplan turbine works?

The water flows through the penstock pipe, and then into the spiral case, which ensure that the water enter the turbine circumferentially and symmetrically, forming a certain circumfluence quantum.

Then through the stay ring into the distributor, whose guide vanes can regulate the turbine discharge and make the water flow into the runner circumferentially and symmetrically. Consequently, the runner revolves and converts hydraulic energy into mechanical energy and then drives the rotor of the generator revolve by the force of the main shaft of the hydraulic turbine, thus converting the mechanical energy into electrical energy. The water, which has gotten out of the runner, flows to the downstream of the river through the draft tube.

kaplan hydro turbine structure

admin –

good product, i will buy it

admin –

How about shipping?